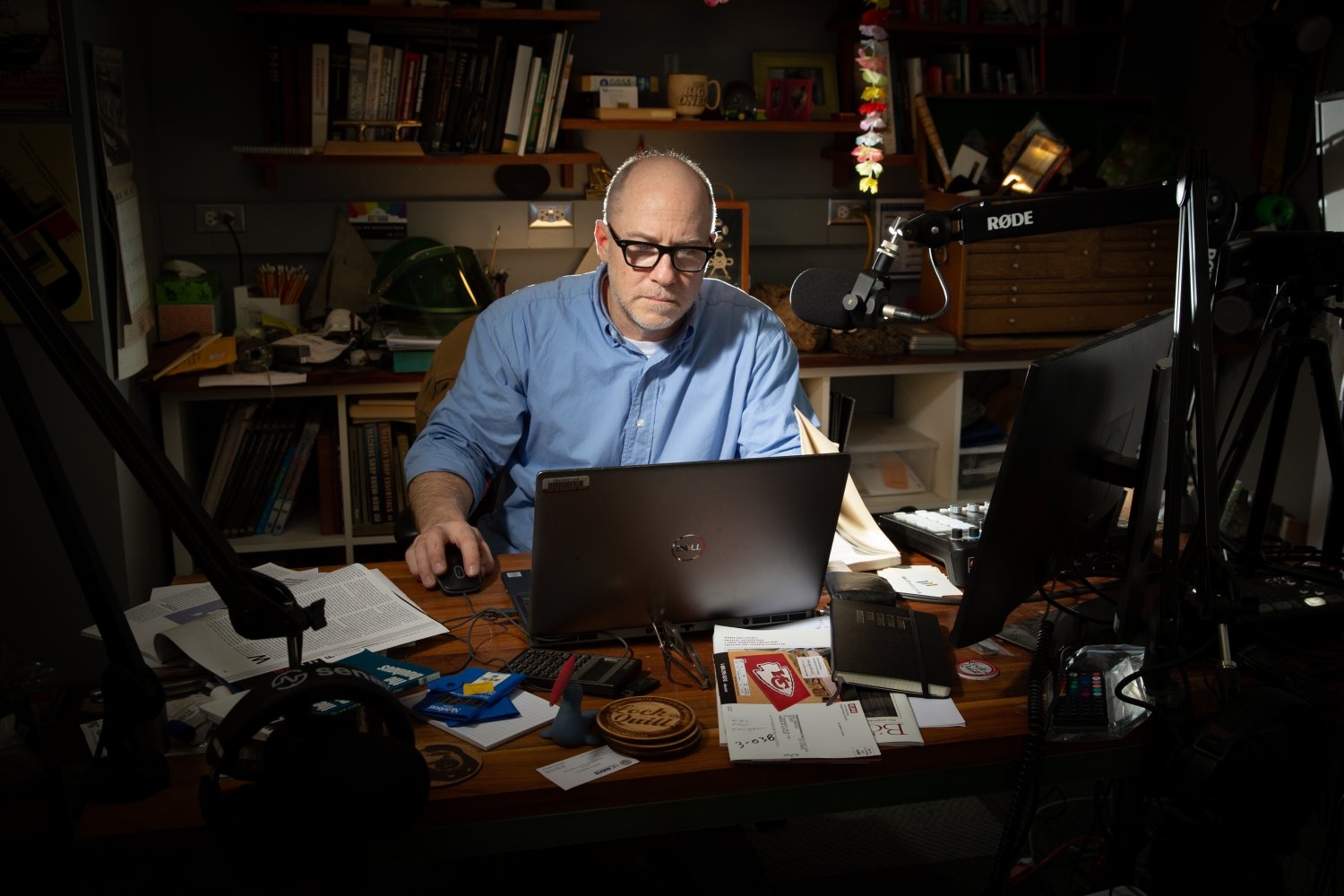

Daniel Braunstein, director of the Pappalardo Undergraduate Teaching Laboratories, found his calling at MIT's hands-on mechanical engineering space.

Michaela Jarvis | Department of Mechanical Engineering

In about 2010, working as a principal and director of mechanical engineering at Continuum, a global innovation firm, Daniel Braunstein says he felt that what he was providing wasn’t as meaningful as he would like. Luckily for MIT’s Department of Mechanical Engineering (MechE), he found an ideal next step.

“I’m kind of cautious about telling this part, but I had been in professional services at that point for 15 years, and I reached a point where I felt like I was not giving everything that I could give,” Braunstein says. “I felt like I could apply myself in a different capacity that might be more profound, that might have a little bit more legs than just, say, the next product development cycle.”

So he headed back to MIT, where he had earned his PhD in 1997.

With his academic background and his experience in industry — where he says he felt job candidates who had just graduated lacked the the gritty, hands-on experience that the industry needed — “I thought I had something to offer the undergrads here.”

Braunstein found his context, and his opportunity to apply MIT’s motto of “mens et manus” (“mind and hand”), when he took over the leadership of the Pappalardo Undergraduate Teaching Laboratories. The Pappalardo Lab is used by students in some of the largest, most important classes in MIT’s MechE department, including 2.007 (Design and Manufacturing 1) and 2.009 (Product Engineering Processes).

Exuberantly praised by many in MechE, the Pappalardo Lab is described as “one of the greatest facilities that has ever existed on the MIT campus” by Steven Leeb, professor of electrical engineering and mechanical engineering.

“It is the gold standard for how to work with engineering students,” Leeb says, adding that the lab teaches students “to take the passion and desire they have to build and actually turn that into reality.”

Leeb credits Braunstein with maintaining and growing the lab’s creative ethos that began when technology entrepreneur and founder of Meditech, Neil Pappalardo ’64, donated money to remake a cluttered steam lab into a sophisticated design studio in the mid-1990s. Much of the physical transformation fell to Braunstein’s predecessor, Richard Fenner. According to Leeb, Fenner also assembled a team of “artists, engineers and humanists — all three in each person, which you don’t usually find.” Braunstein was one of them, and was tapped by Fenner and the department to run the lab, starting in 2011.

Not only Braunstein’s background in academia and industry, but his personality and humor helped encourage a positive atmosphere — and abundant learning — at the lab, his colleagues say.

“One of the best ways to teach is for the student to experience a surprise — to see something they didn’t think was possible or to design something new,” said Leeb. “Danny has an endless bag of tricks to create wonder for the students — and always something funny that goes with it.”

Amos Winter, associate professor of mechanical engineering, agrees that the fertility of the lab environment is Braunstein’s creation.

“He’s no-nonsense when he teaches his lab sections, but he’s so kind and caring, and he’s such an accomplished engineer. He draws students to him and really sets the tone for the lab in his own demeanor and behavior,” Winter says, adding that the Pappalardo Lab is where, “so many students undergo a rite of passage of becoming a mechanical engineer by physically realizing something of their own conception.”

Winter says Braunstein uses creative approaches to classes taught at the lab, such as designing a 12-by-12-foot game board each year for the 2.007 end-of-semester robotics competition with a yearly theme “that’s fun and exciting for the students, but where the challenges stress sound mechanical engineering principles.”

“He doesn’t have to do that,” Winter says. “The details that he’s able to execute add so much color and richness to our program.”

MechE PhD candidate Georgia Van de Zande ’15, SM ’18, who has been part of the teaching staff at the Pappalardo Lab for eight years, also talks glowingly of the lab and Braunstein.

“I have loved seeing how Danny has helped create a space where students can really enjoy the creative learning processes,” she says. “As for the impact on me, Danny is one of many people who have made me feel like Pappalardo is my home on MIT’s campus. At any time of day, students are busy with their projects, and the staff are looking for new ways to engage.”

MechE alumnus Tom Frejowski ’19, SM ’21, who landed a job as a mechanical engineer at Frog Design in New York soon after he earned his master’s degree, says, “Pappalardo was one of the most important places on campus for me during my time at MIT, and that was in large part because of the environment that Danny and the shop staff cultivated. … Moving a design off of paper and into the field is a skill that you can only get better at the more times you do it, and I was very lucky to have a place like Pappalardo to start practicing that skill early.”

One of Braunstein’s most important innovations for making ideas reality is the Pappalardo Apprentice seminar (2.S994), which he refers to as “my biggest mission in recent years.”

Third- and fourth-year undergraduates take the class, and spend half of their time working with sophomores in the robotics design class — in what Braunstein refers to as “community service,” adding that the arrangement reinforces the learning of the older students as it builds community. “There’s no downside to it,” Braunstein says. “And the practical side is we need the help with the sophomores.”

The juniors and seniors spend the other half of the class time in weekly seminars specially designed for them to go deeper into projects with academic lectures focused on metallurgy and fabrication, plus hands-on work in the lab. The juniors build thermal engines as their projects. The seniors, working alongside lab technicians and instructors, take on even more ambitious projects — using advanced computer-aided design and computer-aided manufacturing, making patterns, casting iron and bronzes, machining the parts, and assembling them — actually building devices such as engines from scratch. Braunstein, a sailor with an interest in antique marine equipment, often draws projects from the archives at MIT’s Hart Nautical Collections, allowing students to reverse-engineer marine devices like engines and winches from the late 19th century.

Braunstein says he called the seminar an apprenticeship to emphasize MIT’s relationship with the art — and industrial character — of engineering.

“I did want to borrow from the language of the trades,” Braunstein says. “MIT has a strong heritage in industrial work; that’s why we were founded. It was not a science institution. It was about the mechanical arts. And I think the blend of the industrial, plus the academic, is what makes this lab particularly meaningful.”

Braunstein, frequently described as being wary of the spotlight, is quick to point out that the creativity-inducing atmosphere in the Pappalardo Lab is on account not only of himself, the other instructors, professors, and the students, but also the staff.

“We have a staff that’s made of people who have come up through academic channels, as well as through industrial or vocational channels,” he says. “The lab is effective because of the team we have in place. We work so closely together, and are so aligned, that we can finish each other’s sentences. We are a family, brothers-in-arms, so to speak. I have deep admiration and affection for the team and our chemistry.”

Around Halloween of last year, the “banter among the staff, the practical jokes, ribbing and shop talk” led a student to jokingly suggest that the lab should do a podcast, Braunstein says.

Eleven episodes later, the podcast — named “Lock the Quill” because workers in machine shops often shout that phrase when they hear a whining sound coming from a cutting tool, indicating that the step has been forgotten — has attracted listeners on every continent except Antarctica (and Braunstein says he plans to contact the research station there). The humor and personality of the people in the lab and the interviewees come through, as does the inventively zany sprit of MIT. The episodes are interesting and entertaining even to non-MechE types, perhaps somewhat in the same way that NPR’s “Car Talk” audience extended way beyond car buffs.

Braunstein is an easy-going interviewer — a natural, really — and professors expound on such topics as the design of their latest cardiovascular device, as well as their favorite bands or their intimate knowledge of “the nerd movie canon of the 1980s.”

In addition to their entertainment value, the episodes offer valuable insights and practical information, such as that offered in an interview with a MechE alumna who described her post-graduation path to a great job.

The podcast’s most recent, and illustrious, interviewee was Sally Kornbluth, the new president of MIT. Braunstein and she discussed everything from her bossy chihuahua mix to Carolina barbecue to consolidating MIT initiatives aimed at combating climate change. Kornbluth emphasized that the idea of transforming great ideas into reality, which could be Braunstein’s mantra, is one of things that drew her to MIT.

“MIT is like the pinnacle of that in academia — conceiving of great ideas, and actually making them happen,” Kornbluth says.

Nearly everything occurring at the Pappalardo Lab has to do with the value of creating, Braunstein says.

“I hope the lab is inspiring students to understand at a profound level how creating helps their learning, and how learning helps their creating,” he says. “An outsider’s view is, ‘Oh, you’re teaching them how to fabricate.’ It’s true we’re doing that, but our primary motivation is to instill a profound understanding of creating.

“There are plenty of people who can come up with great ideas. There are far fewer who can come up with the ideas and have the understanding and the skills to be able to convert them into something real. It’s the combination of the two that is going to make our graduates particularly effective.”